20 % shorter

industry maintenance

maintenance shutdowns

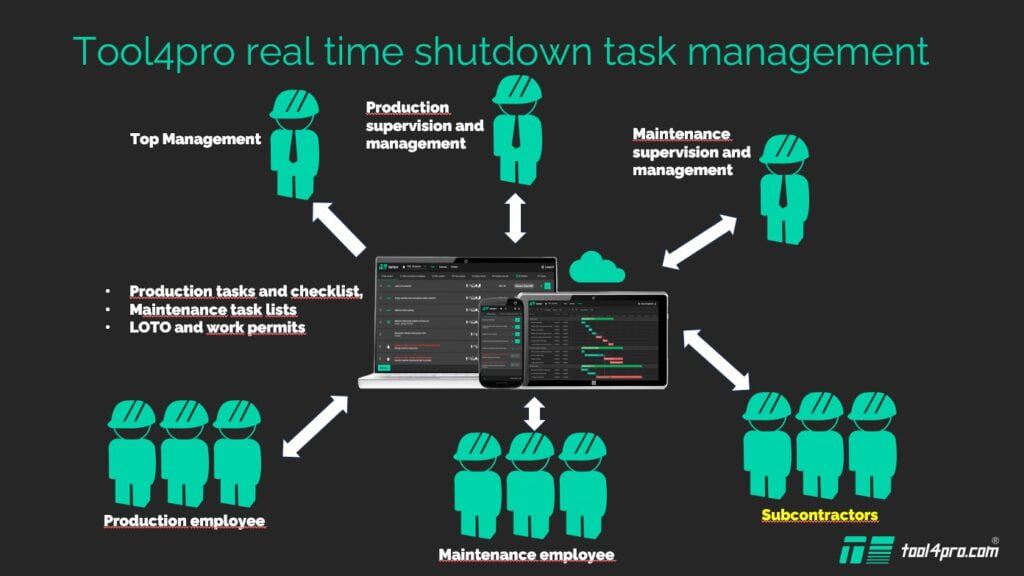

With Tool4pro® you plan, schedule and manage industrial tasks in real time

Tool4pro – More efficient maintenance shutdown (STO / shutdown, turnaround, outage) management for production facilities

Challenges in industrial maintenance shutdowns

Process industry maintenance shutdowns are critical, but they are also functionally demanding and financially expensive. They require:

🔹 Strict scheduling and efficient resource management

🔹 Coordination of multiple parties

🔹 Quick response delays and problem situations

Delays always cost money – with effective management you save time and money.

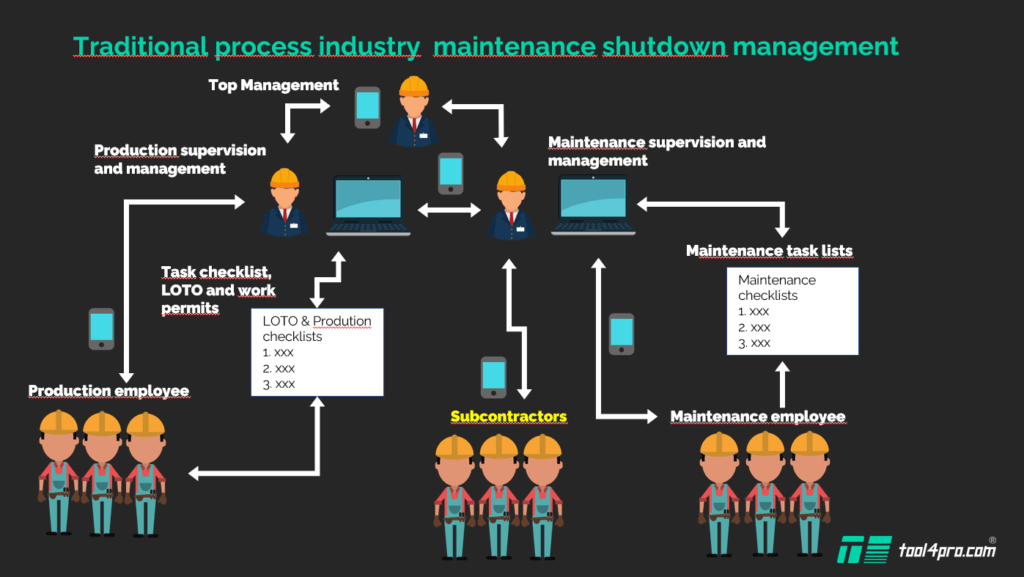

Traditional tools vs. Tool4pro – what's the difference?

Traditionally, maintenance shutdown management has been based on:

❌ For paper lists and spreadsheets that require manual updating

❌ Unclear scheduling, which causes delays and additional costs

❌ Inadequate information flow, which increases the risk of errors

Maintenance management systems (CMMS) alone are not enough to manage maintenance shutdowns, as not all work is covered by them. Tool4pro brings a modern, paperless, real-time and comprehensive solution to this.

Tool4pro - no more paper lists

Tool4pro – The new standard for maintenance shutdown management in process industry

🔹 Planning and scheduling

✅ All jobs and authors in one place – no more separate spreadsheets

✅ Real-time information sharing for all parties

✅ Add necessary instructions, changes and documents for the work

✅ Ssave time and reduce the planning burden

Mobile access:

✅ Manage maintenance downtime work directly from the field

✅ Complete freedom of action – works on all devices with an internet connection

🔹 Electronic work permits

✅ Integrate work permits into tasks – faster and smoother permit process

✅ Avoid paperwork and ensure real-time documentation

🔹 Real-time maintenance downtime management

✅ Track and manage maintenance shutdown in real time

✅ Address problems immediately, which reduces downtime

✅ Optimize resource usage

🔹 User-friendly app

✅ Easy to use for all staff groups and subcontractors

✅ No complicated installations – everything works directly in the browser

🔹 Occupational safety management

✅ Easy management of LOTO (Lockout-Tagout) processes

✅ Work instructions are always available in the field

✅ Clear work dependencies and lock-out ensure safe working

Scorecard and data analytics

✅ Maintenance downtime reporting with the push of a button

✅ Artificial intelligence (AI)-based analytics help optimize future maintenance downtime

✅ Leverage artificial intelligence (AI) to optimize future maintenance downtime

✅ View KPIs and identify areas for improvement

Tool4pro is backed by over 30 years of practical experience in various industrial sectors. Contact our experts and we will tell you how you can reduce maintenance downtime with Tool4pro.

Lasse Kauppinen

CEO

+358408267173

lasse.kauppinen@tool4pro.com

Kare Lappalainen

Expert

+358407536071

kare.lappalainen@tool4pro.com

Tool4pro®, the best solution for managing industrial maintenance shutdowns!

🔐 Tool4Pro – the number one solution for security management

🔹 Work permits and risk assessments are integrated into a real-time system

🔹 Task safety dependencies and LOTO (Lockout-Tagout) processes are in the same environment

🔹 Users can access instructions, documents and safety bulletins directly in the app

🔹 Observations and deviations are recorded quickly, which supports the development of a safety culture

🔹 Safety communication is fast for all parties involved in a maintenance outage

Tool4pro Savings Calculator for Maintenance Shutdowns

See examples of Tool4pro's savings potential below. Try the calculator below and see how much savings you can achieve with Tool4pro.

Paper and board mill example

Average length of the maintenance shutdown 10 h

Average amount of shutdown per year = 12-14 pcs

Sales margin 8000 €/h

Benefits and savings with Tool4pro

Easier and faster task planning

Straightforward task management

Tasks of the maintenance shutdown are performed systematically

Improved information flow

Less wasted time

Savings 20 % in hours = 24 h / year = 224 000 €

Mining concentrator example

Average length of the maintenance shutdown 7 days = 168 h

Average amount of shutdown per year = 2 pcs

Sales margin 50000 €/h

Benefits and savings with Tool4pro

Easier and faster task planning

Straightforward task management

Tasks of the maintenance shutdown are performed systematically

Improved information flow

Less wasted time

Savings 10 % = hours 34 h / year = 1 700 000 €

Calculate savings in maintenance shutdowns with Tool4pro

Annual savings in hours

Annual savings in €

Tool4pro industries

Tool4pro is suitable for all industrial sectors and naturally adapts to the needs of different industries.

Tool4Pro is used, among other things, in mining, paper and energy industry production plantswhere effective management of maintenance downtime is critical.

✔ Reduce downtime

✔ Improve staff job satisfaction

✔ Optimize resources and reduce excess costs

Join our satisfied customers and take your production to the next level!